Forklift Hood

Forklift Hood

It’s an engine cover of a forklift, which is manufactured using the SMC (UP+GF30%) method and assembled on the lower part of the Seat. Major Client Company: CLARK the FORKLIFT

Product packaging and Shipping conditions

Steel Pallet or Wooden Box Contact Supplier, FOB,CIF,CFR terms.Download related information

Product info

| Business Field | Market | Manufacturer | Department |

|---|---|---|---|

| Composites | Mobility | KoreaComposite | Equipment Marketing & Sales Team |

product description

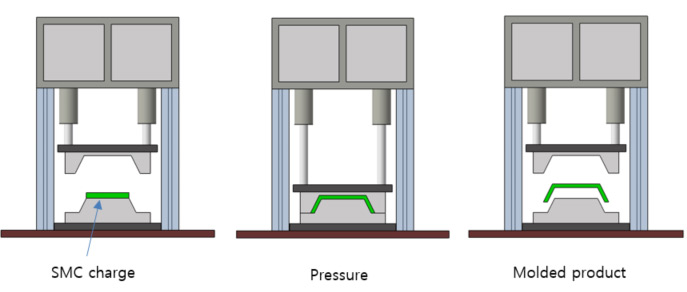

1. About SMC

- SMC is a compression molding material on the Sheet showing good moldability by chemically increasing viscosity after impregnating stiffener(Glass fiber), stuff materials, releasing agent, paint and catalyst, etc. into Unsaturated Polyester Resin. Accordingly, SMC can make adjustment in accordance with the property required by a product because the variable breadth of strength and several material properties depending on stiffener-Glass fiber impregnation & layout level, and stuff materials; thus, SMC puts gelated SMC Sheet on the Mold, and manufactures products by putting heat and pressure using the press.

2. SMC Characteristics

1) Lightening: Available for Implementation of shaped articles’ lightening with low specific gravity(1.9) in comparison with Steel Steel, Fuel efficiency improvement, contribution to reduction in exhaust gas emissions, and high assembly efficiency

2) Strength: Securing of high strong property/ intensity property in comparison with thermoplastic

3) Measurement Precision: Implementation of high measurement precision because the contraction rate(0.04%) after the molding process

4)Thermal Resistance: Thermal resistance is excellent by virtue of thermosetting resin. 5) Flame-Resistance: Resistance to fire with less occurrence of harmful smoke (Halogen marking an environmentally harmful substance, isn’t included.)

6)Electric Insulation: Electric property is excellent such as insulation resistance, and arc-resistivity, etc. along with good tolerance. Due to its excellent insulation characteristic, it is used as a material for an electric meter cabinet and meter box.

7) Corrosion Resistance: It won’t get rusty although paint is peeled off by external shocks.

8)Paint Adhesiveness: Good Paint Adhesion

9) Class A Surface: Surface Levelling is excellent, so it can be used as exterior finishing parts for a passenger car. (When using Class A Material)

3. SMC Molding Mimetic Diagram

4. SMC Material Report

| Item | Temperature | Unit | SMC(G-30%) | |

| Test Standard | Property | |||

| Specific Gravity | 23 degrees | - | KSM ISO 1183 | 1.89 |

| Tensile Strength | 23 degrees | MPa | KSM ISO 527-4 | 96.6 |

| Tensile Modulus | 23 degrees | GPa | - | - |

| Bending Strength | 23 degrees | MPa | KSM ISO 14125 | 208.4 |

| Bending Modulus | 23 degrees | GPa | KSM ISO 14125 | 11.1 |

| Izod Impact Resistance Strength | 23 degrees | J/cm | KSM ISO 180 | 5.9 |

| -30 degrees | - | - | ||

| Heat Deflection Temperature | - | ℃(18.5Kg/㎠) | KSM 3015/A Method | More than 200 |

| Linear Coefficient of Expansion | - | 1/K | ISO 11359-2 | 1.0x10-5 |

| Molding Shrinkage rate | - | - | 0.0004 | |

Supply Ability

- 1..Retained Equipment/500 pm 1 set. 1,000 Ton

application

Contacts

Contact supplier